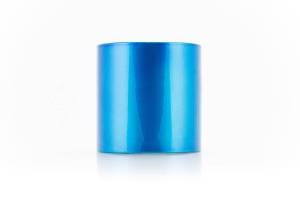

Powder Coat Colors

Powder coating has quickly become one of the most popular alternatives to traditional paint coatings. This type of surface finishing uses a dry powder applied electrostatically as a coating. The part is then cured in an oven for a period of time at temperatures ranging from 380-425*F to form a solid, durable finish. Powder coating not only looks great, but it also lasts longer while providing protection from harmful corrosion. To further improve corrosion resistance for components exposed to the weather we can first apply a Zinc-Rich Base Coat primer before the final color, which offers nearly ten times the corrosion resistance of just a standard coat of powder. Wehrli Custom Powder Coating is housed under the same roof as Wehrli Custom Fabrication. This has enabled us to provide exceptional turnaround time as well as increased quality control measures and packaging of our completed fabricated components. Housing a curing oven 20 ft. long and 8 ft. wide allows us to powder coat items of all sizes. With nearly 100 different colors in stock at our facility, you have many options to choose from.

Don't see one you like? www.prismaticpowder.com has over 5000 colors to choose from! (Non-stocked colors requested in will incur an additional fee) Here is a list of what we have in stock and we are constantly adding to it!

Note: The WCFab emblem on our product comes standard in raw stainless finish, or aluminum depending on the part, unless noted by the color below. Requests for custom color tags are accepted at checkout but will incur an additional $75.00 fee.